The Ultimate Guide to Roll Lamination Machines in 2026?

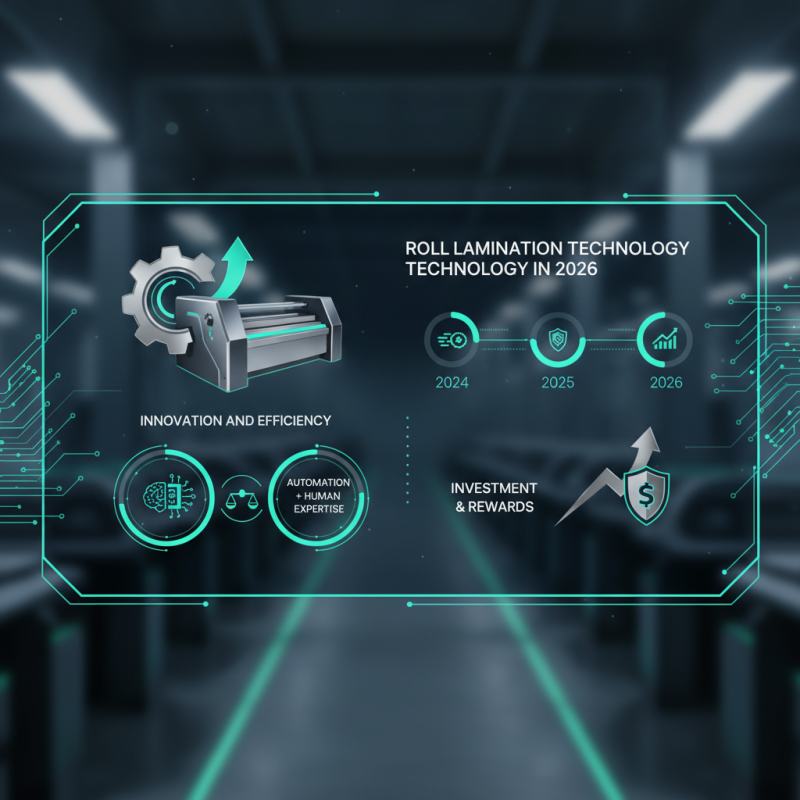

In 2026, the landscape of the Roll Lamination Machine industry is rapidly evolving. Experts like John Harrison, a renowned specialist in lamination technologies, emphasize, "The future of roll lamination machines lies in innovation and efficiency." As businesses seek ways to enhance production, roll lamination machines play a crucial role in meeting these demands.

The technologies involved are not without challenges. While advancements provide faster processing and superior finishes, the reliance on these machines raises questions about skilled labor. Operators need to understand not only the machinery but also its impact on overall productivity. A balance must be struck between automation and human expertise.

Navigating this industry requires continuous learning. The evolving trends often leave businesses in a state of flux. Investing in the latest roll lamination machines can be daunting, yet the potential rewards are significant. It's essential to remain adaptable and reflective about the choices made in this dynamic environment.

Understanding Roll Lamination Machines: A Brief Overview

Roll lamination machines are essential tools in various industries. They enhance the durability and appearance of printed materials. These machines apply a layer of protective film to documents, making them water-resistant and tear-proof. Commonly used in schools, offices, and print shops, they offer both heat and cold lamination options.

When selecting a roll lamination machine, consider its size and speed. A larger machine can handle larger sheets but may require more space. The speed of the machine determines how quickly you can complete projects. Aim for a balance between the two aspects to suit your needs.

Tips: Always keep the machine clean to ensure optimal performance. Regular maintenance stretches its lifespan. It’s also wise to double-check the film type before usage. Not all films work with every machine. Experimenting with different settings can yield unexpected results, but sometimes those “mistakes” turn into unique designs. Embrace the learning curve; not all projects will come out perfect initially.

Key Features and Technologies in 2026 Roll Lamination Machines

As the demand for efficiency in production increases, roll lamination machines have evolved significantly. In 2026, these machines feature advanced temperature control systems. Such systems ensure consistent heat distribution during the lamination process. This is crucial for high-quality output, as uneven heat can lead to defects. New user interfaces are more intuitive, making operation easier. Operators can quickly adjust settings for different materials.

Safety is a priority in 2026 models. These machines are equipped with automatic shutdown features. This minimizes risks related to overheating and operational failures. Improved sensors also enhance monitoring capabilities, providing real-time data during production. Maintenance remains a challenge for many operators, though. Regular checks are necessary to avoid unexpected breakdowns.

Moreover, the speed of these machines is impressive. They can often complete multiple projects in a short amount of time. Yet, speed can sometimes come at the cost of quality. Operators need to balance efficiency with craftsmanship. Finding this balance is essential for optimal results. The integration of smart technology offers new opportunities but also adds complexity to machine operation. As a result, workers must adapt and learn continuously to keep up with advancements.

Benefits of Using Roll Lamination Machines for Different Applications

Roll lamination machines offer diverse benefits across various applications. They enhance durability and provide a protective layer to documents and materials. This durability ensures longevity against wear and tear. Ideal for educational materials, these machines keep posters and charts intact, even in high-use environments. They withstand spills and dirt, making clean-up easy.

Tips: Regular maintenance of your roll lamination machine is essential. Check for any wear in the rollers every few weeks. A well-maintained machine performs better.

For businesses, roll lamination can boost presentation quality. It transforms plain visuals into vibrant displays. Advertising materials become more appealing, which can increase customer interest. However, improper use can result in bubbles or creases. Rushing the lamination process often leads to mistakes. Patience is key for a flawless finish.

Tips: Test different speeds and temperatures on scrap materials. Understanding your machine’s settings can prevent common mistakes. A little experimentation can lead to perfect results.

Comparative Analysis: Roll Lamination Machines vs. Traditional Methods

When comparing roll lamination machines to traditional methods, several key aspects emerge. Roll lamination offers speed and efficiency. It can handle larger volumes quickly, minimizing downtime. This is particularly valuable in environments with high production demands. In contrast, traditional methods often require more manual labor and have longer setup times. This can slow down the overall process, making it less favorable for businesses aiming for rapid output.

However, each method has its drawbacks. Roll lamination machines may require significant initial investment. The complexity of these machines can lead to maintenance challenges. Users must ensure proper training, as improper handling can cause issues. Traditional methods may be simpler but lack the consistency and speed necessary for larger projects. Workers can also tire more easily, impacting quality.

In the end, the choice depends on specific needs. Businesses must weigh the cost of equipment against the benefits of volume and efficiency. Recognizing the strengths and weaknesses of each approach is essential. The goal is to find a balance that meets production demands without sacrificing quality or budget.

Future Trends and Innovations in Roll Lamination Technology

Roll lamination technology is evolving rapidly. In 2026, several trends will shape the industry. First, automation plays a critical role. Automated machines will reduce manual labor. This could increase efficiency significantly.

Sustainability is another key focus. Eco-friendly materials are becoming essential. Manufacturers will seek recyclable films. This shift will appeal to environmentally conscious consumers. Companies may find it challenging to adapt their processes. Balancing cost and sustainability requires careful planning.

Tips: Always research the latest materials before investing. Consider energy efficiency when choosing a machine. Maintenance can be a headache, so schedule regular check-ups. Embracing these trends can lead to success. However, many companies may struggle to keep pace. Adjusting to change is not easy. Consider seeking expert guidance to navigate this evolving landscape.